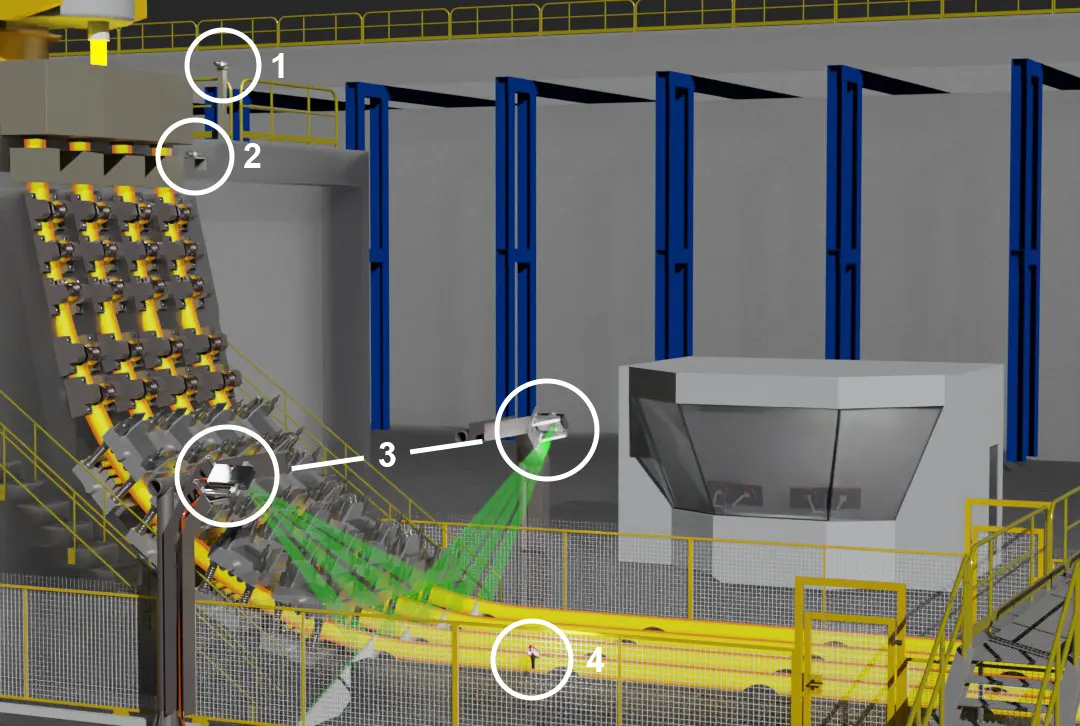

Temperature monitoring in continuous casting plants and rolling mills

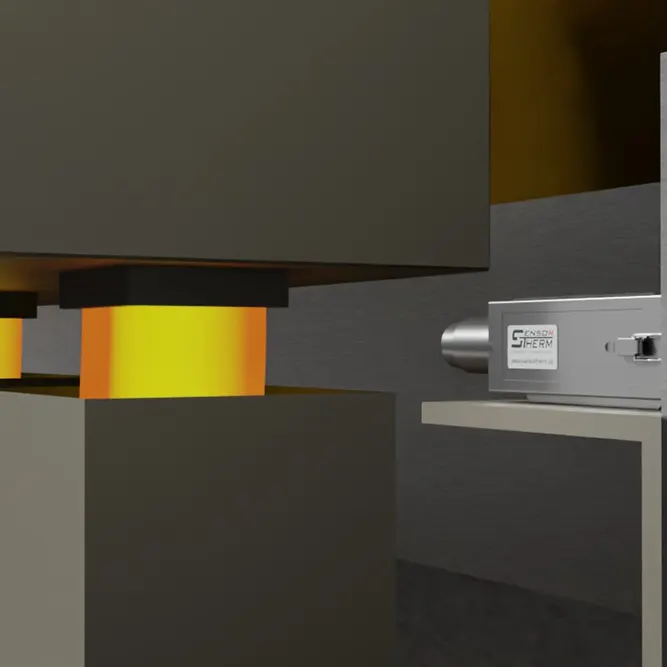

Temperature monitoring in a continuous casting plant is crucial for the quality and efficiency of the process. Two-color pyrometers such as the METIS M311 are preferred for temperature measurement, as they provide reliable results even in the presence of contamination. When used in combination with the GALAXY SC8 in the protective housing, KG28 protective housing, multiple strands can be monitored simultaneously.

Process-relevant measuring points:

1: Measurements at the outlet of the steel ladle

can be carried out with a pyrometer in the cooling housing from a safe distance of up to 10 meters with a spot size of only 51 mm at this distance.

Measurements at the outlet of the tundish

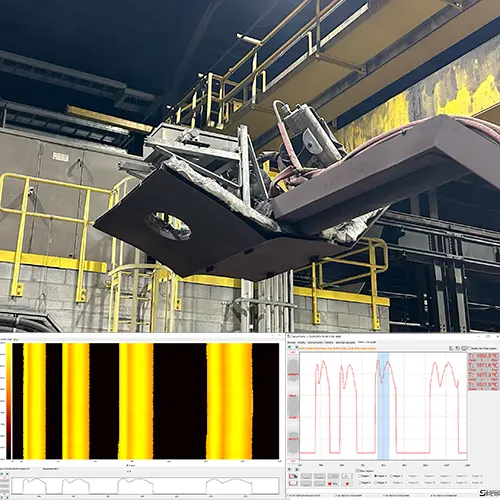

3: Scanning strands

generates temperature profiles of all strands, which can be analyzed using software. A maximum temperature value for each strand allows for easy evaluation.

Intermediate measurements at any location

can be performed with the CAPELLA handheld pyrometer. Even at a distance of 10 m, it has a spot size diameter of only 51 mm.

Non-contact temperature measurement of the moving strand can be performed effectively, even from large distances, using a short-wavelength two-color pyrometer. Since all METIS series pyrometers can be integrated into the GALAXYline scanner, it can be individually adapted to the measurement process. Even if a METIS M311 with a response time of 1 ms isn't fast enough, the high-speed H311 devices can also be installed, for example, to perform very fast measurements of wires in a rolling mill.

Temperature monitoring in a rolling mill is also crucial for the quality and efficiency of the process. Depending on the measuring field coverage, standard METIS M3 pyrometers or two-color pyrometers are used. When used in combination with the GALAXY SC8 in the protective housing, KG28 multiple regions can be defined that can provide multiple temperatures.

Process-relevant measuring points: